Hudong Hydraulic Press Brake 4+1 Axis with DA-53T

- Commodity name: Hudong Hydraulic Press Brake 4+1 Axis with DA-53T

- Product Description

-

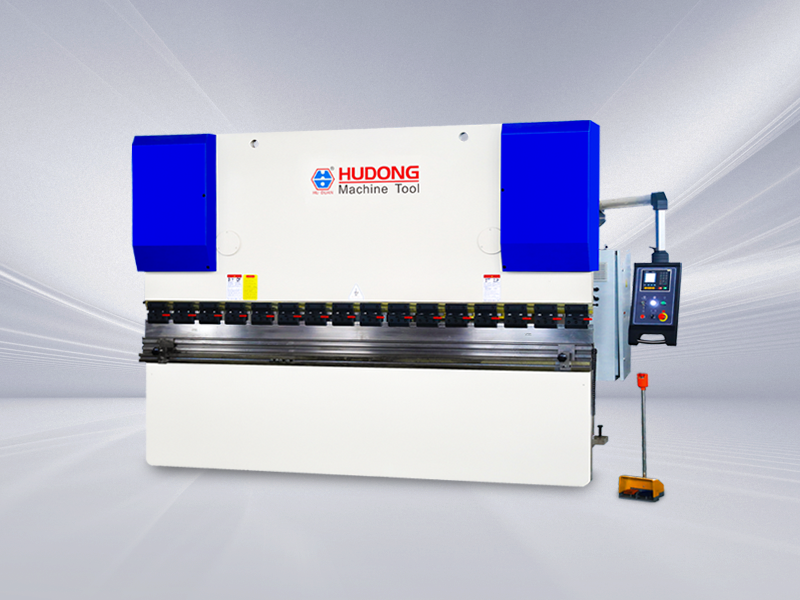

Hudong WF67K-130T/3200 Hydraulic Press Brake with Da-53t Control System

Hudong WF67K-130T/3200 Hydraulic Press Brake with customized Control System is designed for precise metal bending and complex forming tasks. With a capacity of 130 tons and a bending length of 2500 mm, it offers excellent flexibility for various industrial applications. The 4+1 axis configuration ensures accurate multi-step bending operations, while the DA-53T control system provides an intuitive interface for easy programming and real-time monitoring. Its advanced hydraulic system guarantees smooth operation and stable pressure for enhanced productivity. Built for durability, this press brake ensures consistent, high-performance results with minimal maintenance.

No. Product Parameter Value Unit Remarks 1 Bending Force 1300 KN 2 Max. Bending Length 3200 mm 3 Max. Bending Width 100 mm 4 Throat Depth 350 mm 5 Column distance 2700 mm 6 Slide stroke 150 mm 7 Max opening height 455 mm 8 Upper Beam Speed ≤150 mm/s mm/s ≤10 mm/s mm/s ≤160 mm/s mm/s 9 Main Power 11 KW 10 Axes 4+1Axis Y1、Y2、X、R+V 11 Y1、Y2 Repeated Positioning Accuracy ≤±0.01 mm 12 X Axis Max. Stroke 560 mm 13 X Axis Speed ≥250 mm/s 14 X Axis Repeated Positioning Accuracy ≤±0.01 mm 15 R Axis Orientation Range 150 mm 16 R Axis Speed ≥250 mm/s 17 R Axis Repeated Positioning Accuracy 0.1 mm 18 Machine Size 3700 mm mm 1455 mm mm Without Tray 2475 mm mm 19 Weight 8000 Kg

- 3D and 2D graphical touch screen programming mode

- 3D visualisation in simulation and production

- 17" high resolution colour TFT

- Full Windows application suite

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the control's multitasking environment

- Sensor bending & correction interface

- Profile-T3D offline software

Optinal System

DELEM DA-53T

DELEM DA-66T

DELEM DA-69T

Cybtouch 8PS

Cybtouch 12PS

Cybtouch 15PS

Main Parts :

Siemens Main Motor

The German famous brand motor increases the service life of the machine and keeps the machine working in a low-noise environment.

Schneider Electric

High quality electric parts can perform well even the electricity is not stable and customers can easily get the replacement anywhere in the word.

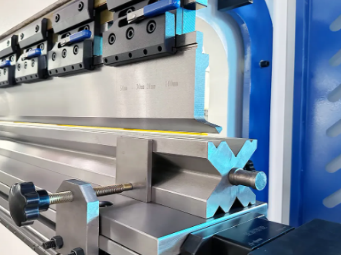

1) Toolings are made of 42CrMo mold steel, with an overall hardness of 47 degrees, excellent quality, and durability. The upper mold is installed on the slider and is fixed by a precision fast clamping device;

2) Using single V and double V molds can make mold replacement convenient and fast, reduce labor intensity, and improve production efficienc.

Rexroth Proportional Valve

The German Rexroth fully closed-loop electro-hydraulic servo high-frequency synchronous control system is adopted to ensure that the machine tool has high stability and high precision in the process of high-speed operation.

Electric Crowning System

- Very precise bending angles

- Europe type dies with 60 mm and 90 mm

- Base can be clamped as well as single dies with 13 mm tang

- Electric crowning with a controller

- Precise positioning and alignment of the crowning table

- Easy and fast usage

Quick Climps

- safe and fast tool change

- substantial improvement in time consumption and related costs

- Secure against tool falling down

- Available in manual, pneumatic and hydraulic models.

- Mounting: Simply from the bottom into the housing, tighten-DONE!

Pedal Switch

South Korea brand foot switch is movable and can stop the machine anytime by the emergency button.

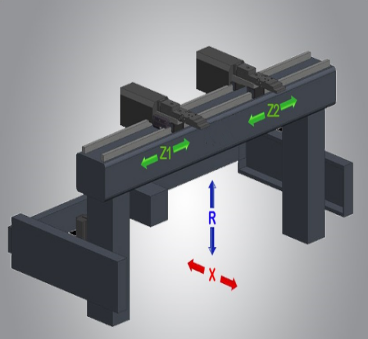

● X-axis: controls the horizontal movement of

the back gauge, which is the device that

positions the metal sheet for bending.

● Y-axis: controls the vertical movement of

the ram, which is the device that applies

the bending force to the metal sheet.

● Z-axis: controls the depth of penetration of the ram into the die, which determines the angle of the bend.

● R-axis: controls the horizontal movement of the bending die, which can be used to create bends with varying radii.

Optional Parts

Servo main motor

SDKELI Laser protection

Keywords