200 tons 2500 4+1 Axis with DA-53T

- Commodity name: 200 tons 2500 4+1 Axis with DA-53T

- Product Description

-

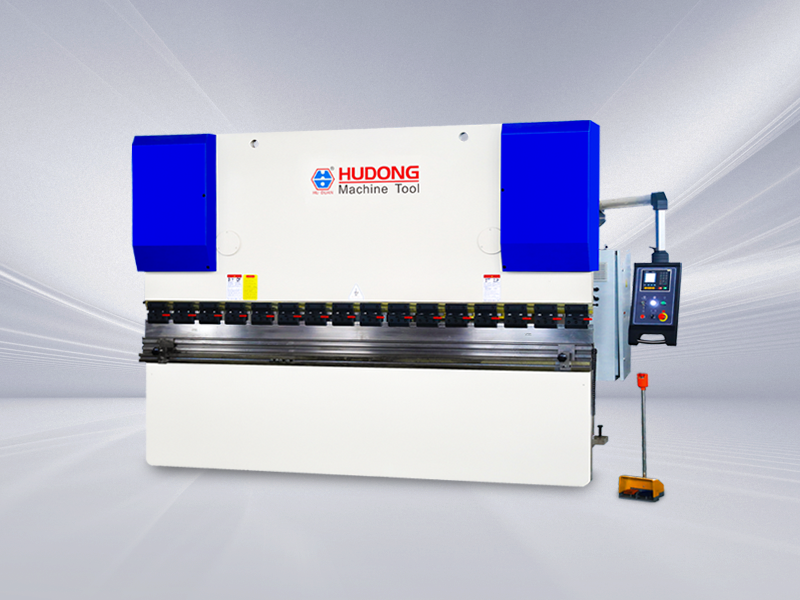

WF67K-200T/2500 CNC Hydraulic Press Brake with Da-53t

Hudong WF67K-200T/2500 Hydraulic Press Brake with customized Control System is designed for precise metal bending and complex forming tasks. With a capacity of 200 tons and a bending length of 2500 mm, it offers excellent flexibility for various industrial applications. The 4+1 axis configuration ensures accurate multi-step bending operations, while the DA-53T control system provides an intuitive interface for easy programming and real-time monitoring. Its advanced hydraulic system guarantees smooth operation and stable pressure for enhanced productivity. Built for durability, this press brake ensures consistent, high-performance results with minimal maintenance.

No.

Product Parameter

Value

Unit

Remarks

1

Bending Force

2000

KN

2

Max. Bending Length

2500

mm

3

Max. Bending Width

100/260

mm

4

Throat Depth

400

mm

5

Column distance

2100

mm

6

Slide stroke

150

mm

7

Max opening height

490

mm

8

Upper Beam Speed

≤130

mm/s

mm/s

≤9

mm/s

mm/s

≤140

mm/s

mm/s

9

Main Power

15

KW

10

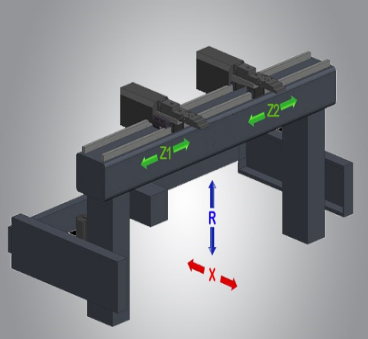

Axes

4+1 Axis

Y1、Y2、X、R+V

11

Y1、Y2 Repeated Positioning Accuracy

≤±0.01

mm

12

X Axis Max. Stroke

560

mm

13

X Axis Speed

≥250

mm/s

14

X Axis Repeated Positioning Accuracy

≤±0.01

mm

15

R Axis Orientation Range

150

mm

16

R Axis Speed

≥250

mm/s

17

R Axis Repeated Positioning Accuracy

0.1

mm

18

Machine Size

3700

3000

mm

1455

1620

mm

Without Tray

2475

2500

mm

19

Weight

10000

Kg

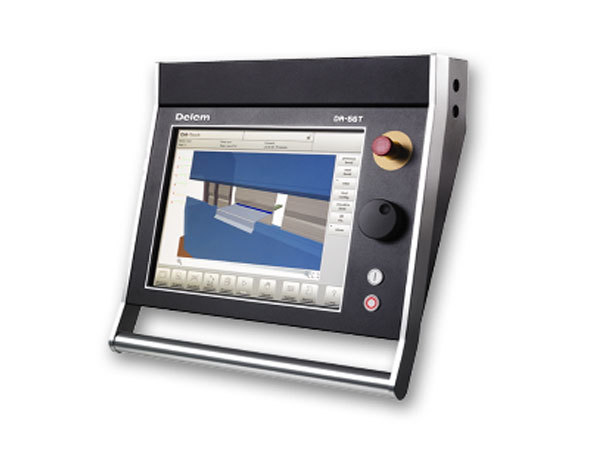

- 3D and 2D graphical touch screen programming mode

- 3D visualisation in simulation and production

- 17" high resolution colour TFT

3D and 2D graphical touch screen programming mode

3D visualisation in simulation and production

17" high resolution colour TFT

Full Windows application suite

Delem Modusys compatibility (module scalability and adaptivity)

USB, peripheral interfacing

User specific application support within the control's multitasking environment

Sensor bending & correction interface

Profile-T3D offline software

- Optinal System

DELEM DA-53T

DELEM DA-66T

DELEM DA-69T

DELEM DA-53T

DELEM DA-53T

DELEM DA-53T

Main Parts :

Siemens Main Motor The German famous brand motor increases

the service life of the machine and keeps the machine working in

a low-noise environment.

Schneider Electric High quality electric parts can perform

well even the electricity is not stable and customers can

easily get the replacement anywhere in the word.

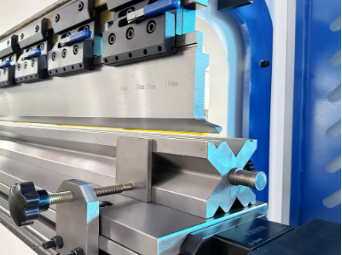

1) Toolings are made of 42CrMo mold steel, with an overall

hardness of 47 degrees, excellent quality, and durability.

The uppe mold is installed on the slider and is fixed by a

precision fast clamping device;

2) Using single V and double V molds can make mold

replacement convenient and fast, reduce labor intensity,

and improve production efficienc.

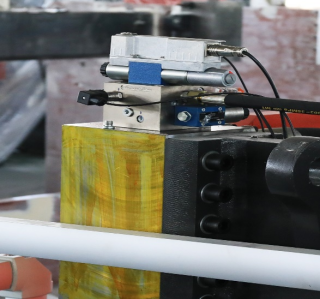

Rexroth Proportional Valve The German Rexroth fully

closed-loop electro-hydraulic servo high-frequency

synchronous control system is adopted to ensure that

the machine tool has high stability and high precision

in the process of high-speed operation.

Electric Crowning System

Very precise bending angles

Europe type dies with 60 mm and 90 mm

Base can be clamped as well as single dies with 13 mm tang

Electric crowning with a controller

Precise positioning and alignment of the crowning table

Easy and fast usage

Quick Climps

safe and fast tool change

substantial improvement in time consumption and related costs

Secure against tool falling down

Available in manual, pneumatic and hydraulic models.

Mounting: Simply from the bottom into the housing,

tighten-DONE!

Pedal Switch

South Korea brand foot switch is movable and can

stop the machine anytime by the emergency button.

● X-axis: controls the horizontal movement of the back

gauge, which is the device that positions the metal

sheet for bending.

● Y-axis: controls the vertical movement of the ram,

which is the device that applies thebending force to

the metal sheet.

● Z-axis: controls the depth of penetration of the ram

into the die, which determines the

angle of the bend.

● R-axis: controls the horizontal movement of the

bending die, which can be used to create bends with varying radii.

Optional Parts Servo main motor SDKELI Laser protection

Keywords